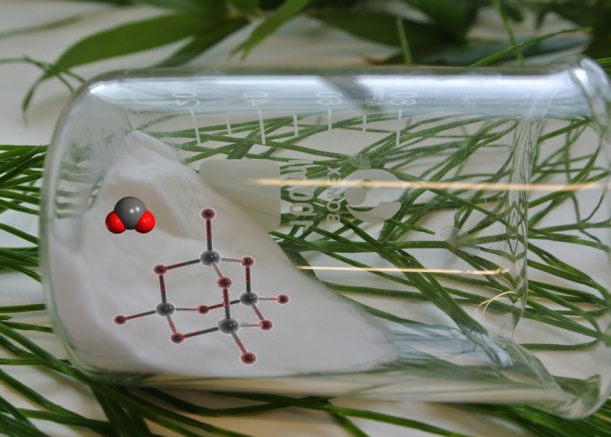

A beaker of silica (silicon dioxide) on a bed of horsetail, Equisetum arvense. Also showing the molecular structure of silicon dioxide and the tetrahedral arrangement adopted in the solid state.

Imagine my surprise when I saw a little glass container with dry brown needles, labelled “Horsetail, Devon, UK” on the desk of a Professor of Inorganic and Materials Chemistry in Texas (Jeffrey L. Coffer at TCU). Horsetail (Equisetum arvense), an invasive, deep-rooted weed, along with members of the grasses family (Poaceae), which includes bamboo, rice, grass and sugarcane, accumulates silica (silicon dioxide) throughout its stems and leaves. This silica, perhaps more familiar from little sachets of drying agents when you buy new shoes, can be converted into mesoporous silicon, used as a benign additive in food and cosmetics, but is also of interest in biomedicine as a template for bone and cell growth. Jeff and his colleagues have developed a chemical process to achieve this conversion, potentially allowing the use of agricultural waste and weeds for the production of silicon.

1. The main image shows a beaker of silica gel lying on some horsetail leaves. Glass beakers are used everywhere in the chemical laboratory to hold liquids and solids. Silica gel, a form of silicon dioxide (SiO2), shown as a single molecule and in a small version of its crystalline arrangement of SiO4 tetrahedra, is often used in column chromatography to purify reaction products and separate mixtures of compounds. Like other forms of chromatography, e.g. thin-layer chromatography (TLC, covered in our posts on nicotiana and vanilla) and high-pressure liquid chromatography (HPLC, covered in our post on chilli), this process relies on the components of a mixture having different affinities for the stationary phase and solvent(s) used, so they travel at different speeds, allowing their separation. In column chromatography, this is achieved by filling a glass column with silica gel or alumina, soaking this with solvent and then using more solvent to move the mixture through the column, collecting small fractions of the eluent (solvent and hopefully a single component) at the bottom. The column is not allowed to run dry until all the desired components have been collected. Solvent can then be evaporated from the different eluents to give pure compounds. Fig. 1 shows a column being prepared. Column chromatography is a time-consuming but effective part of much laboratory work, and the stationary phases used are key to this process.

The field horsetail, Equisetum arvense, is sometimes called a “living fossil”, because plants in the Equisetum genus are the last surviving members of the Equisetaceae family which used to grow to the size of trees and contributed significantly to the oil and coal deposits we rely on today. For this reason they are represented in the Evolutionary Dell in Bristol’s Botanic Garden, as described in our Summer Post last year. We have looked at hyperaccumulators of different elements in a recent post on phytomining, and grassy plants seem to rely on silicon to both strengthen their structures and for defense against herbivores. Horsetail plants are also promoted as a medicinal herb “great for skin and hair”, because the human body is thought to need silicon for the biosynthesis of elastin and collagen, key components in youthful skin. However, very few scientific studies seem to have been published and the Medline Plus site for Horsetail rates the evidence as insufficient to assess effectiveness.

Silicon is the second most abundant element in the earth’s crust, so you might wonder why there could be a need to use plants to extract it from the soil. Firstly, this silicon is locked up in different minerals, most commonly the silicates, which need to be reacted further to convert them into pure silicon, usually via silica. Silica is also present in the crust, and one of its purest forms is quartz, an incredibly tough, hard and brittle material (for lots of structural detail about quartz, follow this link). Again, further chemical reactions are needed to convert this into silicon. Secondly, we actually want mesoporous silicon for biomedical applications and as a food additive, and for this the material needs to have pores with a width between 2 and 50 nanometers, giving it a very large surface area. For comparison, microporous materials have pores smaller than 2 nm, and, you guessed it, macroporous materials have pore sizes in excess of 50 nm. Mesoporous structures can be achieved by etching silicon, for example on the silicon wafers used in microprocessors and solar cells, but the reagents used for etching are pretty nasty and, depending on the pore size needed, you lose quite a lot of the silicon during the etching process. Plants, such as the horsetail and bamboo mentioned above, accumulate silicon in the form of silicon dioxide or silica from the soil, and integrate it into the structure of their roots, stems and leaves, giving a porous structure from the outset. Chemical conversion into silicon can be achieved, as shown by Jeff and his co-workers (Silicon 2012, 4, 259-266), under fairly benign conditions, preserving the pores and so giving access to mesoporous silicon without the need for etching. The purity of this material gained from plant feedstocks (and bamboo worked better than horsetail in their trials) is not quite good enough for microprocessors, but it is sufficient for other uses and there is scope for further optimising this process.

2. Silicon dioxide can be converted to silicon by a number of reduction-oxidation (redox) processes, such as the carbothermic reduction which takes place in an electric arc furnace, SiO2(s) + 2 C(s) -> Si(s) + 2 CO(g) at temperatures in excess of 1900 oC, and the magnesiothermic reduction, SiO2(s) + 2Mg(s) -> Si(s) + 2 MgO (s). The magnesiothermic reduction can be initiated at temperatures around 540 oC, but is exothermic, meaning the reaction gives off heat, which can affect the pore size and surface area of the silicon created, because particles fuse together.

Redox reactions are quite common in chemistry and involve the transfer of electrons between different compounds. We teach the mnemonic “OILRIG” to students – Oxidation Is Loss (of electrons), Reduction Is Gain (of electrons), and in both of the above reactions the silica is reduced to elemental silicon, involving the transfer of electrons from carbon or magnesium to the silicon. To keep track of the electron transfer, chemists tend to use oxidation numbers, based on relative electronegativities (the tendency of an atom to attract an electron pair), and these are assigned according to the following rules:

- Oxidation state of atoms in uncombined elements (e.g. N2, P4, S8, He) is 0.

- In neutral molecules, the sum of the oxidation states is 0.

- For simple ions, the oxidation state equals the charge on the ion (e.g. for Fe2+ the oxidation state = +2).

- In complex ions, the sum of the oxidation states equals the charge on the ion.

- Hydrogen has the oxidation state +1 in all its compounds, except for metal hydrides (-1).

- Oxygen has the oxidation state -2 in all its compounds, except for peroxides (e.g. H2O2) and OF2.

- Electronegativity can give a guide to the assignment of oxidation states in (simple) compounds: The more electronegative atom is usually assigned to a negative oxidation state, while the less electronegative atom adopts a positive oxidation state.

Applying these rules to the reactions shown above, we can now see that silicon is in the +4 oxidation state in SiO2, and then gaining 4 electrons to reach the elemental oxidation state of 0. Carbon is going from a 0 oxidation state to +2, and both stoichiometry and electron transfer are balanced by using 2 equivalents of C. In the magnesiothermic reduction, elemental magnesium, again with oxidation state 0, reacts to give MgO, where it has an oxidation state of +2.

In the soil, quartz and other sources of silica (it is present in most types of rock, including igneous, sedimentary and metamorphic) react with water to form orthosilicic acid, H4O4Si, according to the following reaction equation: SiO2 + 2 H2O -> H4O4Si, and you can use the rules above to work out whether this is a redox reaction or not.*

3. The industrial conversion of silica to silicon often involves high temperatures or, where mesoporous structures are desired, etching or corrosion with hydrofluoric acid (HF), producing volatile SiF4 gas and soluble hexafluorosilicic acid, H2SiF6. In contrast, plant-derived silica is nanostructured and this structure is preserved if the conversion into silicon can be achieved at low enough temperatures to prevent sintering, i.e. the fusing together of particles. The magnesiothermic reduction described in section 2 and used by Canham, Coffer and co-workers (Silicon 2012, 4, 259-266) above can achieve this, but is exothermic, making sintering more likely to occur. This has been controlled by the addition of a salt (sodium chloride powder). Materials need to be washed repeatedly with hydrochloric acid both before and after reduction to remove other impurities. Despite this, purity in the initial trials described is around 96%, too low for biomedical applications. However, the authors suggest that this can be improved if the process is developed further. Imagine every gardener’s glee if that pesky horsetail patch, as well as much agricultural waste, could become a useful feedstock of silica and silicon in the future…

Contributors: Jeff Coffer (idea), Natalie Fey (images, research, writing), Jenny Slaughter (editing).

*It is not, the Si oxidation state stays as +4 throughout.